Ensuring product quality and precision is a top priority for our company, PINSI, when it comes to manufacturing linear guides and ball screws. We employ a variety of methods to ensure the highest level of quality in our products.

Firstly, our production and processing methods are carefully designed to produce high-quality products. Our manufacturing process utilizes advanced equipment and technology to ensure accuracy and precision. We use CNC machines as well as wire EDM to precisely cut steel for our products, and our technicians carefully monitor each step of the process to ensure the correct specifications are met.

Secondly, the steel we use for our products is subjected to a heat treatment process that enhances its strength and durability. We use high-quality steel that is carefully selected for its specific properties, and our heat treatment process ensures that the steel has the required mechanical properties for optimal performance.

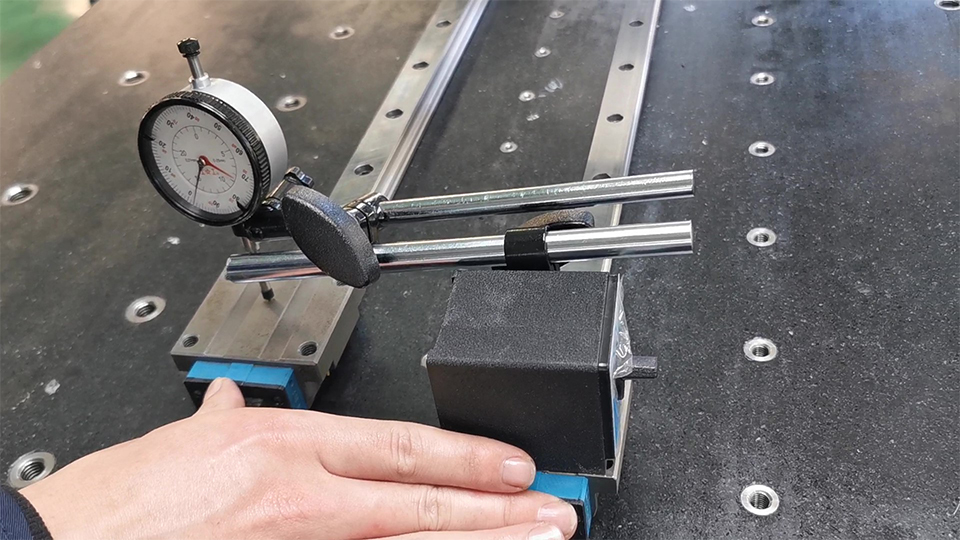

Lastly, we perform post-precision testing on all of our products to ensure that they meet the required specifications. This includes testing for accuracy, straightness, and surface finish, among other factors. We use specialized equipment to measure the products at different stages of the manufacturing process to ensure that they meet our high standards for precision.

At PINSI, we understand that precision is critical in the performance of our products. That is why we are committed to ensuring that every product that leaves our facility is of the highest quality and precision possible. From production and processing to heat treatment and testing, we take great care to ensure that our customers receive products that meet their exacting requirements.

+8615622924499

+8615622924499

+8615622924499

+8615622924499