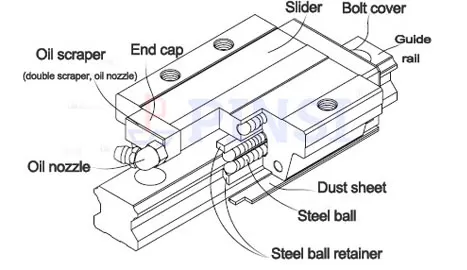

● Rolling circulation structure: slider, guide rail, end cover, steel ball, steel ball retainer, etc.;

● Lubrication system: oil nozzle, oil pipe joint;

● Dust-proof system: oil scraper, film dust seal dust-proof piece, guide rail bolt cover, metal scraper.

The linear guide is a kind of rolling guide. By using steel balls to perform an infinite rolling cycle between the slider and the guide rail, the load platform can easily make lines with high precision along the guide rail.

Sexual movement. Compared with the traditional sliding guide, the friction coefficient of the rolling guide can be reduced to 1/50 of the original. Since the friction at startup is greatly reduced, it is relatively less hassle-free.

Effective motion occurs, so it can achieve um-level feed and positioning. Coupled with the design of the binding unit between the slider and the guide rail, the linear guide rail can withstand up, down, left and right forces at the same time.

Loads in all directions, the above display characteristics are not comparable to traditional sliding guides. Therefore, if the machine can cooperate with rolling screws and use linear guides as guides, it will definitely be able to significantly improve equipment accuracy and mechanical efficiency.

This guide rail is designed as HG series linear guide rail, which has its own characteristics compared with other linear guide rails.

1. Automatic centering ability

The DF (45°-45°) combination from the arc groove will have elastic deformation of the steel balls and transfer of the contact points during installation, even if the installation surface is somewhat biased

The difference can also be absorbed internally by the first planning speed, resulting in the effect of automatic centering ability and obtaining high-precision, stable and smooth motion.

2. Interchangeable

Due to strict control over manufacturing accuracy, the dimensions of linear guide rails can be maintained within a certain level, so the guide rail sliders are interchangeable and can be stored separately to reduce

storage space.

3. High rigidity in all directions

The use of four rows of arc grooves and a 45° contact angle of four rows of steel balls allows the steel balls to achieve an ideal two-point contact structure, which can withstand the impact from up, down, left and right directions directional load; if necessary, preload can be applied to improve rigidity.

+8615622924499

+8615622924499

+8615622924499

+8615622924499