Why Noise Matters in the Laboratory

Laboratories housing equipment like scanning electron microscopes (SEM), atomic force microscopes (AFM), optical imaging systems, and MRI machines are designed for minimal vibration and acoustic interference. Traditional linear motion systems can generate noise through.

● Vibration: Transmitted through the structure of the equipment, disturbing samples and blurring images.

● Airborne Noise: Audible sounds that can disrupt quiet work environments and sensitive acoustic measurements.

● High-Frequency Sounds: Generated by imperfect rolling elements or resonance, which can interfere with sensitive electronics and sensors.

Low-noise linear guides are engineered from the ground up to mitigate these factors, ensuring that the motion system supports, rather than hinders, your research.

Key Features of Low-Noise Linear Guide Rails

Our linear rails are specifically designed for lab applications, incorporating several noise-dampening technologies

1. Advanced Sealing and Lubrication

Dust and debris are primary culprits in noise generation. Our rails feature double-sealed end caps and non-contact labyrinth seals to prevent contamination. Furthermore, they are pre-lubricated with a special, long-life grease that minimizes friction and maintains smooth, quiet operation over millions of cycles without re-lubrication, which itself can introduce contaminants.

2. Optimized Recirculating Elements

The core of the noise reduction lies in the design of the ball or roller circuit. We use:

Precision-Grade Balls: Manufactured to ultra-tight tolerances for uniform size and perfect spherical shape, reducing erratic movement and vibration.

Patent-Pending Circuit Design: The recirculation path is engineered to minimize impact and turbulence as the balls re-enter the load zone, eliminating the characteristic "clicking" sound of standard guides.

3. Superior Manufacturing and Precision

Every component is manufactured to super-precision tolerances (e.g., Precision Grade P5 or higher). This ensures perfect geometry and alignment, eliminating internal stress, uneven rolling motion, and the resultant vibration that leads to noise.

4. Vibration-Dampening Materials

While the rail itself is typically hardened steel for durability and precision, critical components like carriage housings and mounting blocks can be crafted from specialized alloys or composites that naturally absorb and dampen vibrational energy, preventing its transmission to the machine frame.

Material Selection for Corrosion Resistance

Laboratories often involve exposure to chemicals, solvents, and humidity. Our low-noise rails are frequently available in stainless steel (e.g., SUS440C or SUS304) versions. This provides excellent corrosion resistance, ensuring long-term performance and smooth, quiet operation even in harsh lab environments, without the risk of rust-induced friction and noise.

Applications in the Laboratory

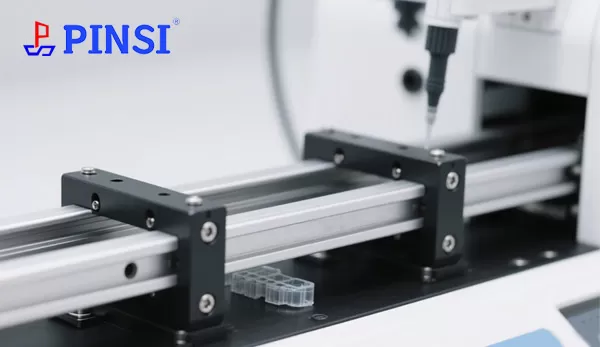

Our ultra-quiet linear motion systems are ideal for a wide range of lab automation and precision equipment.

● Automated Microscopy & Slide Scanning: Moving slides between the objective and camera without disrupting the image capture process.

● DNA Sequencers & Liquid Handling Robots: Ensuring precise, vibration-free movement of pipettes and samples.

● Sample Manipulation in MRI & CT Scanners: Providing motion inside shielded rooms where noise must be absolutely minimized.

● Optical & Laser Systems: Positioning lenses, filters, and mirrors without introducing alignment errors.

● Cleanroom Automation: Where both particulate generation and acoustic noise are strictly controlled.

Conclusion: A Sound Investment in Research Quality

Choosing the right motion components is a critical decision in laboratory instrument design. By selecting linear guides engineered for low-noise, low-vibration operation, you directly invest in the accuracy, repeatability, and reliability of your research outcomes. You create a better working environment and protect your sensitive investments in high-end analytical equipment.

Ready to eliminate noise from your design? Contact our engineering team today to discuss your specific application requirements. We provide custom linear motion solutions and samples to ensure your lab instruments perform at the pinnacle of precision and silence.

+8615622924499

+8615622924499

+8615622924499

+8615622924499