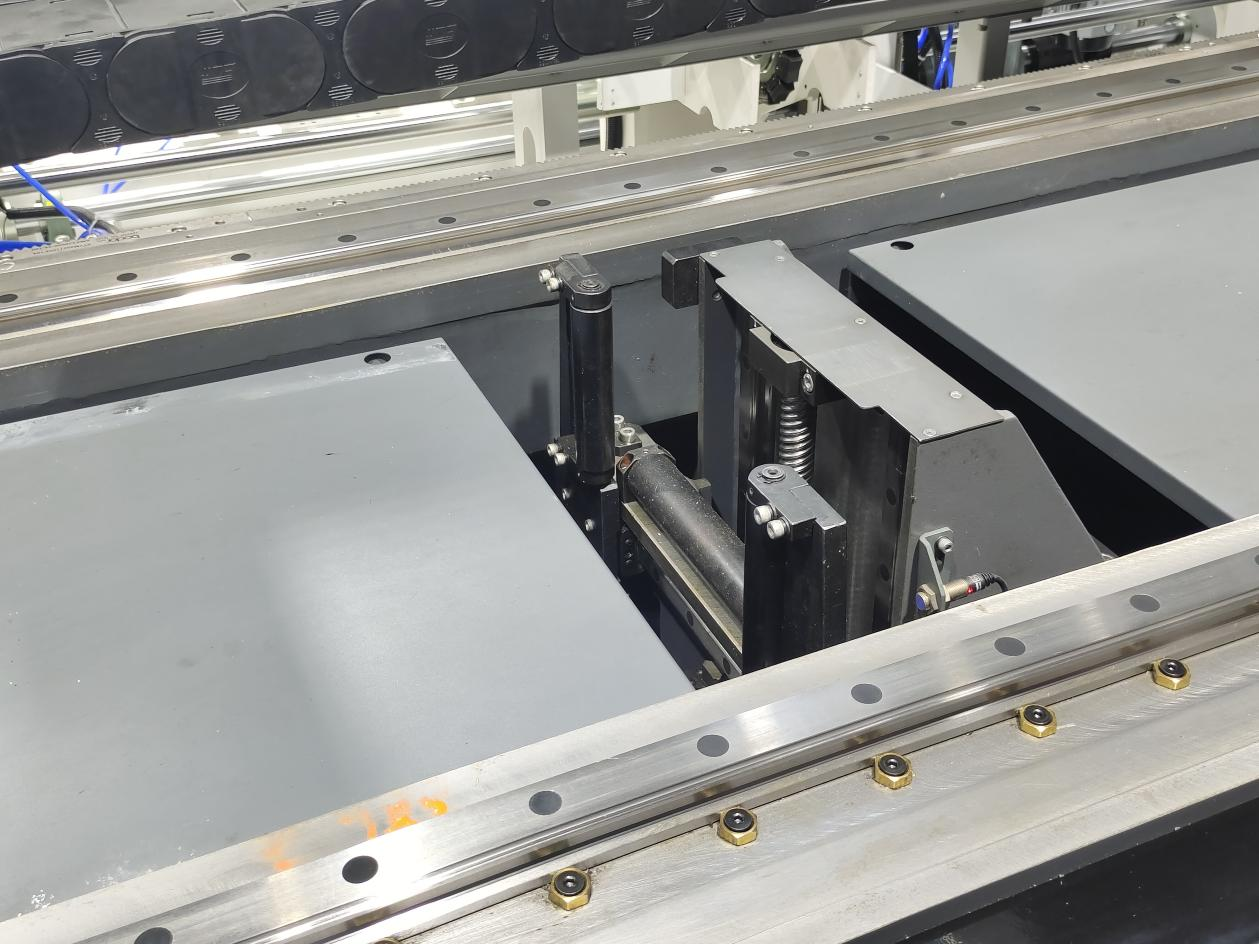

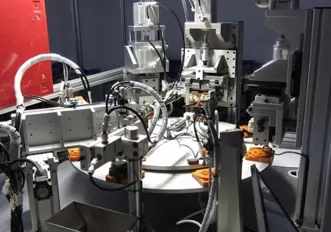

Ball screws and linear guides work together in transportation machinery to provide precise linear motion for conveyor systems, automated storage and retrieval systems (ASRS), and other material handling applications. The ball screw converts the rotary motion of the motor into linear motion, while the linear guide provides support and guidance to the moving carriage.

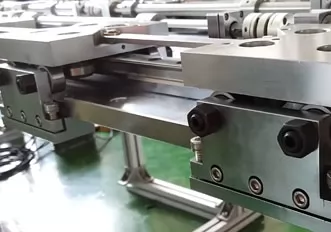

In order to make transportation machinery operate normally, it is important to ensure proper alignment and maintenance of the ball screws and linear guides. Regular cleaning and lubrication can help to prevent wear and ensure smooth operation. It is also important to choose the correct size and type of ball screw and linear guide for the application, taking into account factors such as load capacity, speed, and precision requirements.

The advantages of using ball screws and linear guides in logistics transportation machinery include high precision, high load capacity, and low friction. These components are able to operate at high speeds while maintaining accuracy and repeatability, which is essential in conveyor systems and other logistics applications. The low friction of ball screws and linear guides also helps to reduce wear and extend the service life of the components.

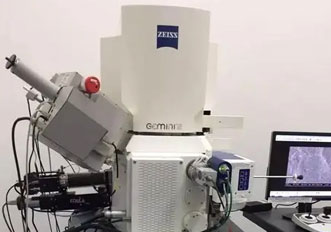

Overall, the combination of ball screws and linear guides provides a reliable and efficient solution for the precise linear motion required in transportation machinery. Proper selection, installation, and maintenance of these components can help to ensure optimal performance and reduce downtime in logistics operations.

+8615622924499

+8615622924499

+8615622924499

+8615622924499